Share this article:

PROJECTSHOWCASE

TECK - HIGHLAND VALLEY COPPER

Highland Valley Copper is an open pit mine

operation and process plant. The process plant

uses autogenous and semi-autogenous grinding

and flotation to produce metal in concentrate from ore.

CUSTOMER INFORMATION

Highland Valley Copper Mine, owned by Teck Resources

The largest open pit copper mine in Canada

Electrical Load: DC Rectifiers, VFD’s, Cycloconverters, Induction or Synchronous Motors, Large Electric Shovels

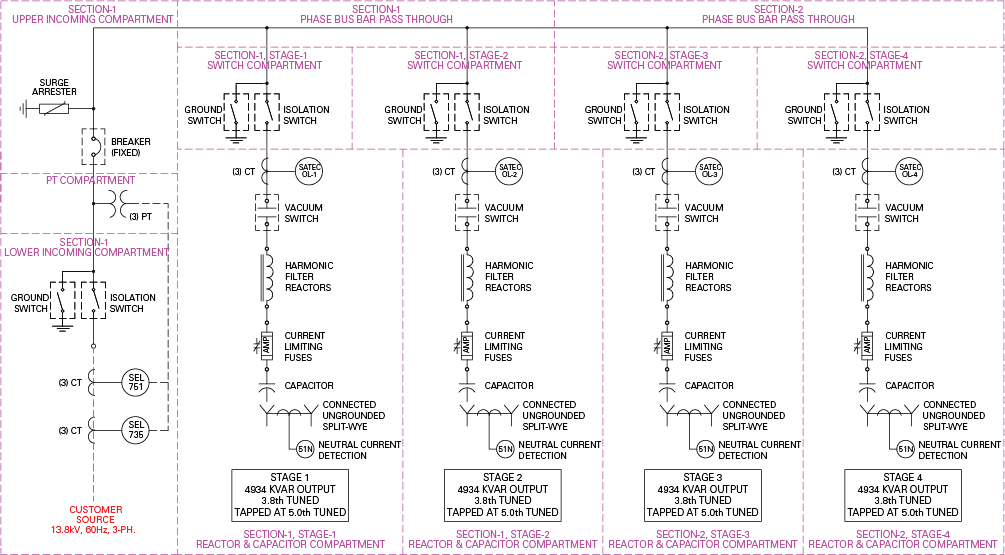

EQUIPMENT DESCRIPTION

Primary Purpose: Power factor correction, prevention of harmonic resonance, harmonic filtering, IEEE 519 compliance

Equipment Type: Multi-Tuned harmonic filter bank

Ratings: 13.8 kV, 60 Hertz, 95 kV BIL, 19.7 MVAR (effective), 3-Phase, 4-Stage, 4-Step, 3.8th Tuned

SITE CONDITIONS

South Central British Columbia, Canada

Max. Temperature: 28.3°C (82.9°F)

Min. Temperature: -37.2°C (-34.9°F)

Annual Precipitation: 217.9 mm (8.57 in)

Extreme Snow Depth: 81 cm (31.8 in)

PRODUCT FEATURES

SEL735, SEL751 Relay Protection System and Control System with Arc Flash Detection

The SEL Relay logic controls and protects equipment and communicates with mine’s DCS system.

Main Incoming Disconnect Switch / Ground Switch and Fixed Mounted Vacuum Circuit Breaker

This allows for direct connection to mine’s main overhead bus bar. The filter bank did not require a feeder breaker in main switchgear.

Compartmentalized Enclosure Design

Design consisting of 12 isolated compartments, including: control, incoming isolation / ground switch, PT, main incoming fixed breaker, main bus, stage isolation / ground switch (1 per stage,

4 total), and 4 stage compartments.

Stage Isolation / Ground Switches for Each Filter Stage

Allows for safe maintenance of one stage while the others remain in operation.

Multi-Tuned Harmonic Filter Reactors

Allows for the quick and simple conversion from a 4 stage, 3.8th tuned notch harmonic filter system to a multi-tuned 4 stage, 3.8th / 5th / 7th / 7th notch tuned harmonic filter system.

Harmonic Overload Protection

On each notch tuned filter stage.

Thermal Overload and Blown Fuse Detection

On capacitor fuse as well as split-wye protection on each stage.

Reinforced Base Channel

For mounting on to pylons. Equipment also features an enclosure floor and externally mounted lights for substation illumination.

Commissioned in August, 2014

Catwalk with removable handrails was installed around the perimeter to allow for easy access to the equipment

Heavy dust buildup at the site required Pylon mounting. This simplified cable entry, avoiding the need to excavate the existing ground grid

Cables were free-air rated and run on an exposed cable tray under the gear

Struthers Tehcnical Solutions, Ltd

http://strutherstech.com/

Engineering involvement included identifying the need for power factor correction and harmonic filtering

Cost / Benefit analysis for the equipment

Equipment spec, document prep, bid review, arc flash analysis, relay programming, and on-site commissioning

3-LINE DIAGRAM

Follow us on social media for up-to-date news, videos, and other information: