Kinder Morgan Energy Partners Adds an actiVAR

Share this article:

Monday Sept. 15, 2014

Kinder Morgan Energy Partners and Tennessee Gas Pipeline Company worked with NEPSI and T-Star Engineering and Technical Services to provide engineering, product application support, and an actiVAR at their Morehead, KY compressor station. The compressor station had been experiencing failed motor starts due to voltage drop during starting of their 10,000 HP, 13.8kV synchronous motor driven compressors.

.png)

Background

Kinder Morgan Energy Partners' Tennessee Gas Pipeline (TGP) is a 13,900-mile pipeline that transports natural gas from Louisiana, the Gulf of Mexico and south Texas to the Northeast United States, including New York City and Boston.

TGP compressor stations along the pipeline adjust pressure, maintain and monitor flow, and provide real-time information about natural gas transmission.

Loss of capacity through compressor or motor failure has significant financial and contractual impacts, both major points of concern for TGP.

Case Study

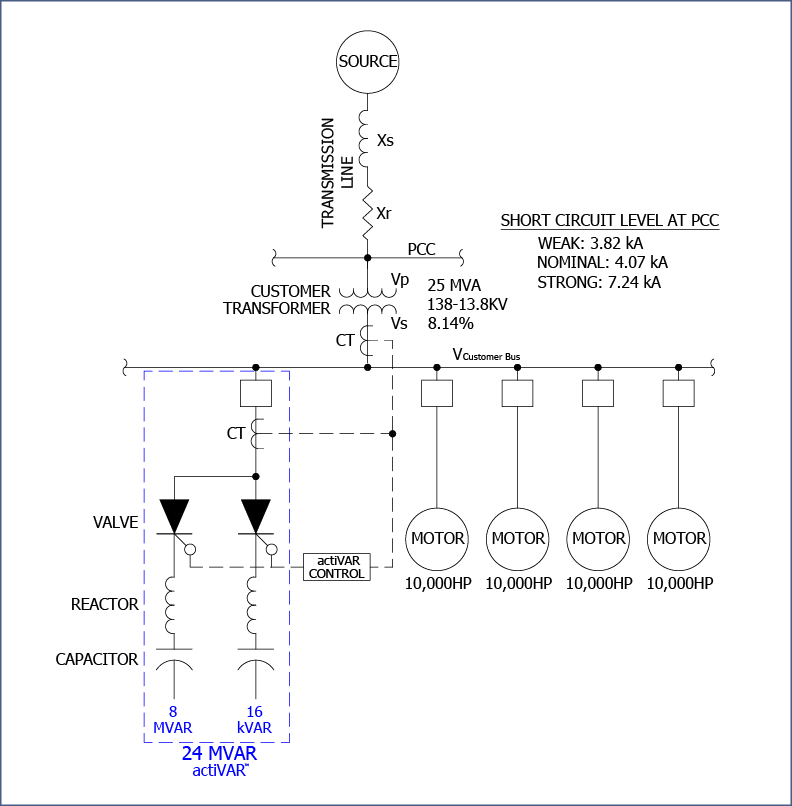

TGP's Morehead, KY Station 110, has four 13.8kV, 10,000 HP, 1800 RPM Synchronous Motors (see Figure 1). Station motors would fail to start in low voltage conditions.

Starting torque varies by the square of the voltage, and large motor starts on weak systems often have problems starting. Here starting voltage sags to 84% (due to high reactive power flow during starts) resulted in attempted starts with 70% of rated torque.

Kinder Morgan provided a full service contract to NEPSI, collaborating with T-Star Engineering and Technical Services, for an actiVAR. The expedited contract included:

- A motor starting study using dynamic simulation software to size and predict actiVAR performance

- Design and supply of a fully assembled actiVAR including all protection, control, and disconnecting means

- Startup, commissioning, and onsite tuning of actiVAR

- Verification of actiVAR performance against study predictions

System Details

Figure 1 below is a one-line diagram of the TGP substation showing electrical service, actiVAR, and synchronous motors. The 138kV source impedance provides a nominal fault current of near 4.0kA. The station transformer is rated 25 MVA with short circuit impedance rating on its own base of 8.14%. Compressor motors are each rated 10,000 HP and are started sequentially.

Study results showed a 24 MVAR shunt-connected actiVAR would be required to keep the system voltage near 1.0 Per Unit during starts.

Figure 1 - Compressor station one-line diagram showing compressors, actiVAR, and electric supply details.

actiVAR FEATURES AND FUNCTIONS

The actiVAR monitors load current and system voltage at high speeds, correcting voltage sags caused by loads 180 times a second. Sophisticated controls provide unique features like "boost during synch." In event of operating problems, the actiVAR is capable of self-diagnosis and operation in partially-failed ("run-flat") modes.

Designed for "drop-in ease", actiVAR systems are available with integral breakers and relays. Installation typically require a concrete pad, power and ground connections, a load CT and station power. This one was ready to go 24 hours after arrival onsite.

Performance Results

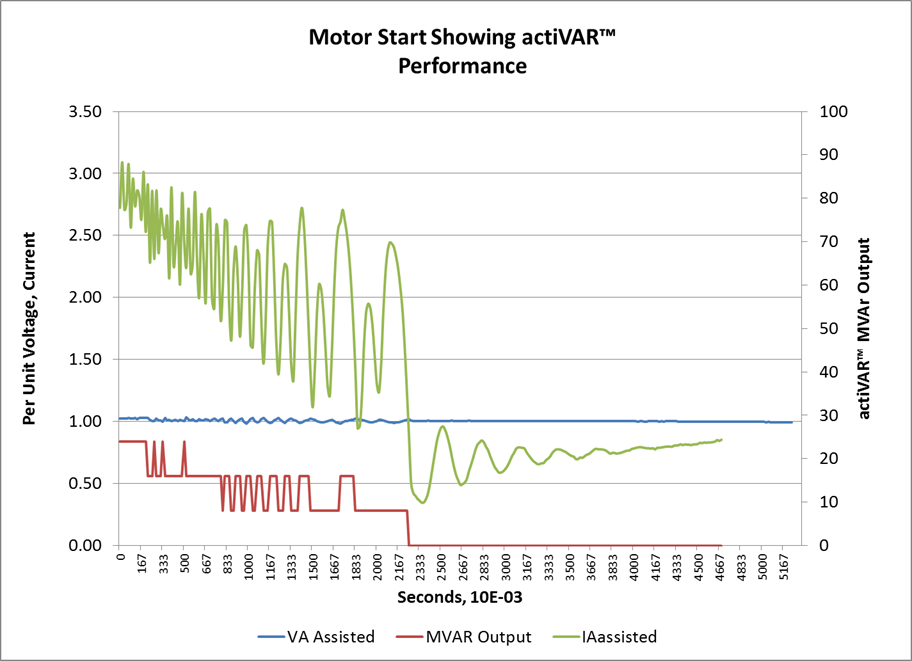

Figure 2 below provides a plot of the actiVAR data log showing its performance starting motors during field commissioning.

The blue line in the plot shows the system voltage is held near 1.0 per unit through the entire starting period.

The green line shows the starting current at near 3.0 per unit full-load current initially, and then decreasing to near 1.0 per unit as the motor comes up to speed.

The red line shows the actiVAR reactive power output in MVAR. The actiVAR had a binary sizing arrangement allowing the two stage bank to come on in 8 MVAR increments.

Figure 2 – Plot of actiVAR Data Log Showing Performance During Motor Start

Conclusion

The actiVAR performs as predicted in our study. It provides reactive power on a cycle-by-cycle basis, while maintaining system voltage to near 1.0 per unit for the full starting period of the motor. Motor start failures have been eliminated.

Follow us on social media for up-to-date news, videos, and other information: